SURELIA ENGINEERS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SURELIA ENGINEERS

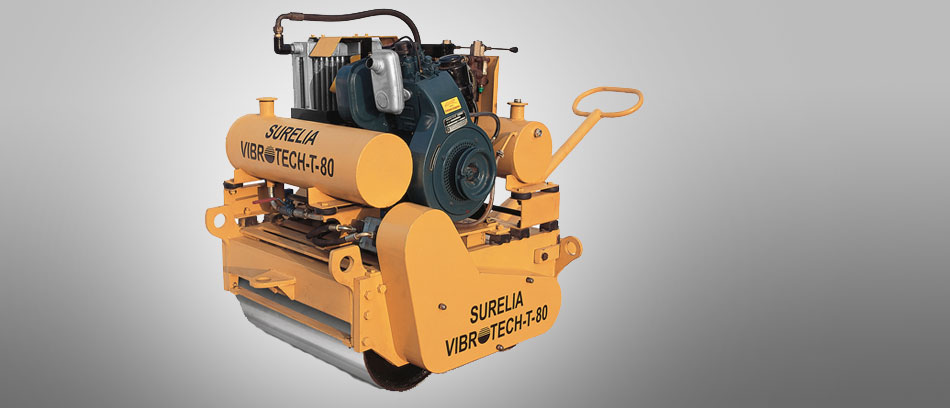

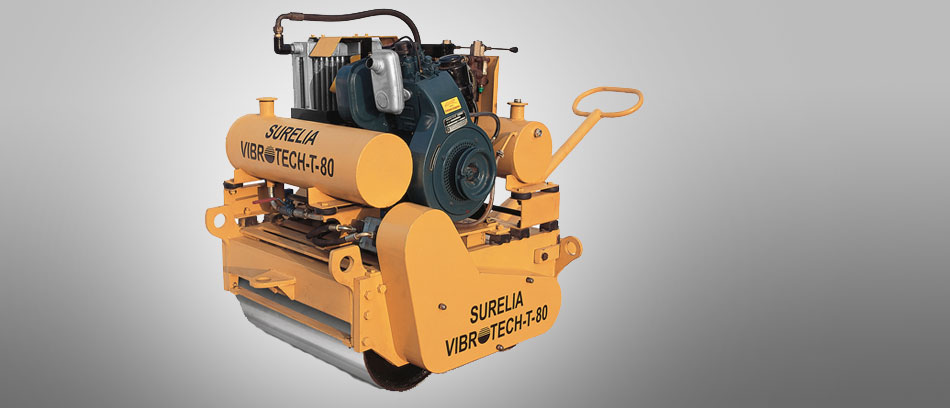

Walk Behind Vibratory Roller

Walk Behind Vibratory Roller

Due to its compact design, the VIBROTECH T-80 is the ideal roller for small repairs in both Base and asphalt courses. Widening of roads, Horticulture, Landscape Gardening, Internal roads in complex.

Its low overall height and closely set drums provides a clear view of the entire working area, ensures high manoeuvrability.

Inspite of its relatively low weight, the use of double drums, ensures high Compaction performance & has necessary gradient climbing ability.

NO GEAR BOX, HYDRUALIC DRIVE hence VERY LESS DOWN TIME, No failure. Total Maintenance Free Machine.

Speed for both Forward & Reverse remains same & being Hydraulic, it has more power then Mechanical Type Rollers.

Features

Double compaction with each pass. Two “V” belts synchronizes the action of both vibrators. The eccentric weights are positioned 180 deg. Out of phase to each other. Water Sprinkler Type Gravity.

Drive

- Traction drive via hydraulic motor.

- Positive with spring action.

Mobile Concrete Placer

Mobile Concrete Placer

"SEW" Mobile Concrete Placer is available in 56 Feet length, pouring at the height of 27 feet & ability to fold for Towing without removing discharge hopper.

Mechanical power for the conveyor is provided by 25 HP (19 Kw) Kirloskar Engine, which drives a Hydraulic Double Pump. The Main Hydraulic pump provides power for functions above A) & B), while the secondary pump powers functions C), D) & E).

Powered Functions

- Belt Travel.

- Self Propelled Drive.

- Articulated Boom.

- Hydraulic Steering & (Pivoting of Towing Wheel & 360o).

- Elevating Boom.

Mobile Concrete Batching Plant

Mobile Concrete Batching Plant

Salient Features

- Available in 15 M3 / 20 M3 / 25 M3 / hr. Capacity.

- Rigid construction of main chassis; fabricated from rolled mild steel material.

- Mixer – PAN type, for continuous mixing.

- Replaceable liner Tiles and Tips in the mixer.

- Compact design for easy of transportations & shifting by towing also.

- Loading of aggregate / Sand hoppers by Wheel loader / JCB.

- PLC based Control system facility of Automatic & Manual mode, Cable-remote type control Device, print facility.

- USB based removable storage.

- Fully Automatic Plant with Electronic Weighing of Aggregate/Sand/Water/ Cement.

- Plant can be erected & commissioned within two day.

- Inbuilt Water and Additive tank.

- Complete plant can be transported in one 40 foot trailer.

- With Discharge Belt Conveyor.

- Plant only requires Electric Power Supply, Water Piping / Aggregate Sand feeding

In Line Mobile Concrete Batching Plant

In Line Mobile Concrete Batching Plant

Salient Features

- Available in 25 M3 / hr. Capacity.

- Rigid construction of main chassis; fabricated from rolled mild steel material.

- Mixer – PAN type, for continuous mixing.

- Replaceable Bottom Liner, Side Liner and Tips.

- Compact design for easy of transportations & shifting by towing also.

- Loading of aggregate / Sand hoppers by Wheel loader / JCB.

- PLC based Control system facility of Automatic & Manual mode, Cable-remote type control Device, print facility.

- USB based removable storage.

- Fully Automatic Plant with Electronic Weighing of Aggregate/Sand/Water/ Cement.

- Water by digital meter.

- Plant can be erected & commissioned within two day.

- Inbuilt Water and Additive tank.

- Complete plant can be transported in one 40 foot trailer.

- Plant only requires Electric Power Supply, Water Piping / Aggregate Sand feeding.

Truck Mounted Batching Plant

Truck Mounted Batching Plant

Salient Features

- Available in 15/20 M3 / hr. Capacity.

- Quick mobility.

- No foundation required for installation.

- Rigid construction of main chassis; fabricated from rolled mild steel material.

- Mixer – PAN type, for continuous mixing.

- Planetary Gear box for mixer drive.

- Replaceable Bottom liner Side liner and Tips.

- Inbuilt Water and Additive tank.

- Fully Automatic Plant with Electronic Weighing of Aggregate/Sand/Water/ Cement.

- Accommodates 9 different mix recipes.

- PLC based Control system facility of Automatic & Manual mode, Cable-remote type control Device, print facility.

- USB based removable storage.

- Plant only requires Electric Power Supply, Water / Aggregate Sand feeding.

Ready Mix Concrete Plant

Ready Mix Concrete Plant

Four Bin System

4 Bin aggregate. Feeder unit. Feeder bins are provided with pneumatically operated, radial gates for coarse /fine discharge. Sand Bin is provided with vibrator.

Gathering / Weighing Conveyor

Aggregates are discharged sequentially according to predefined set values on to the Gathering Conveyor. The Gathering Conveyor assembly is suspended on 4 load cells As soon as desired recipe of aggregates accumulates gathering conveyor discharges the material on to the Slinger Conveyor. The Gathering Conveyor & Slinger Conveyor are provided with idlers roller guides & return roller.

Slinger Conveyor

Slinger Conveyor discharges aggregate to the retention hopper.

Weighing system for Cement, Water & Additives

CEMENT

Cement will be feeded from cement storage silo to cement weighing hopper, mounted on 3 nos. load cell fitted with butterfly valve, hopper is provided with pneumatic vibrator & two inlets for two screw conveyors (WAM Italy make).

WATER WEIGHING TANK

Water will be pumped by water pump from reservoir [Buyer’s Scope]. Water tank is suspended on load cells, fitted with butterfly valve. which is actuated by pneumatic cylinder. Water will be directly discharged into the mixer.

ADDITIVES

Comprise of admixture flask tank of capacity 10 Liters with feeding pump.

Retention Hopper

Temporary Storage Hopper is provided with vibrator & it is utilized for Holding the batch of 4 aggregates before feeding to the pan type mixer.

Pan Type Mixer

Pan Type Mixer is fixed on the basic structure of the plant. Mixer having 7 arms and shell is reinforced with replaceable high wear resistant Liners. The aggregates, cement, water & additives are discharged to Pan Mixer. After homogeneous mixing the batch is discharged to the Transit Mixer by hydraulic system.

Computerised Control Cabin

"SCADA" Type Controller

Proxy switch for each control point (Gates)

Display Monitor.

Storage for 99 different type of mix proportions.

Preset batch controls the no. of batches for a transit mixer.

Provision for printing operating data like – Mix Proportion, Batch weight, total no. of Batches, Sub total, Gross Total, etc.

Automatic & manual control.

8’ x 7’ cabin size.

Wet Mix Plant

Wet Mix Plant (Soil Stabilization)

Four Bin System

4 Bin aggregate. Feeder unit with storage bin 12 Mt each for 100 TPH & 19 Mt each for 160 & 200 TPH. Feeder bins are provided with auxiliary belt conveyor. Sand Bin is provided with vibrator.

Steep bin walls and valley angles allow free flow of aggregates from the feeders minimizing hang up of materials in the corners and bridging with sticky aggregates. The bins are equipped with adjustable gates. The belt feeders can have either fixed or variable speed drives. The optional variable speed drive with proportional controls, offers greater flexibility and accuracy of operation.

Pug Mill Unit

The Twin shaft pug mill design provides fast, continuous and homogenous mixing of aggregates. The shafts are mounted on extra heavy duty anti-friction bearings for smooth function and extended life. The wear resistant alloy steel selection for paddle arm and tips ensures a long life. The liner plates are corrosion and abrasion resistant.

Water Arrangement

Self-priming pump and spray bar with water flow meter for accurate metering. Control from the main operating panel.

Controls and Automation

The weather protected cabin houses the user-friendly controls that are specifically designed for construction site condition. The control panel ensures sequential operation of the various drives and precise control. An emergency stop in the form of a push button located close to the pug mill unit affords additional safety.

Storage Silo

The storage silos 12 Ton in 100 TPH (Option as required) & 25 Ton in 160 & 200 TPH br1m , easy to erect. Anti Segregation hopper at discharge point minimizes mix segregation. Fast opening hydraulically operated gates facilitate quick discharge of mix material into the truck without segregation.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.